Anodizing

Anodizing Services

What is Anodizing?

Anodizing, or aluminum anodizing, is an advanced electrochemical process that strengthens aluminum, enhances corrosion resistance, and creates versatile surface finishes. From vibrant colors to matte or glossy textures, anodizing allows aluminum to be both durable and visually appealing.

Applications of Anodizing Types

Type I (Chromic Acid Anodize):

- Characteristics: A thin film with a grayish color.

- Applications: Provides high corrosion resistance but is not very hard. It is typically used in the aerospace industry.

Type II (Sulfuric Acid Anodize):

- Characteristics: A thicker film that offers good color absorption.

- Applications: Suitable for decorative applications and general industrial components.

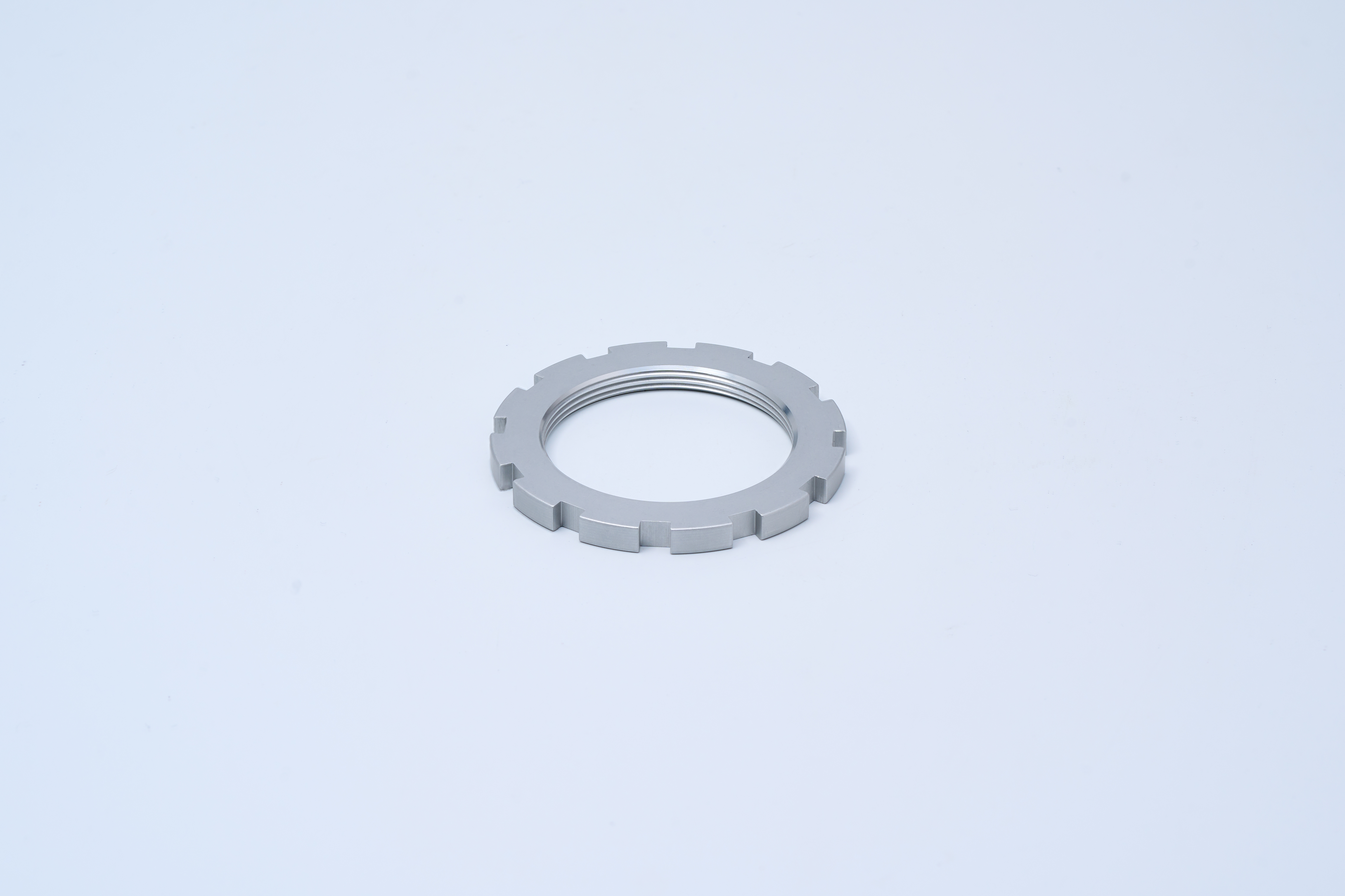

Type III (Hard Anodize / Hard Coat):

- Characteristics: A very thick film (25–100 microns) that is extremely hard and highly wear-resistant.

- Applications: Ideal for machinery parts and components that require high strength.

Selecting Film Thickness

The choice of anodized film thickness depends on the intended application:

Film Thickness - Typical Applications

5–10 microns: General decorative applications

10–25 microns: Exterior architectural applications

25–50 microns: Heavy industrial use, machinery parts

50–100 microns: Hard anodizing for specialized applications

Key benefits of anodizing include:

- Strengthens the surface of aluminum

- Resistant to corrosion from weather and chemicals

- Reduces friction for improved performance

- Enhances aesthetics through coloring and dyeing options

- Environmentally friendly, with no heavy metal residues

- Suitable for both indoor and outdoor applications

Capabilities and Selling Points of ZIP Metal Works

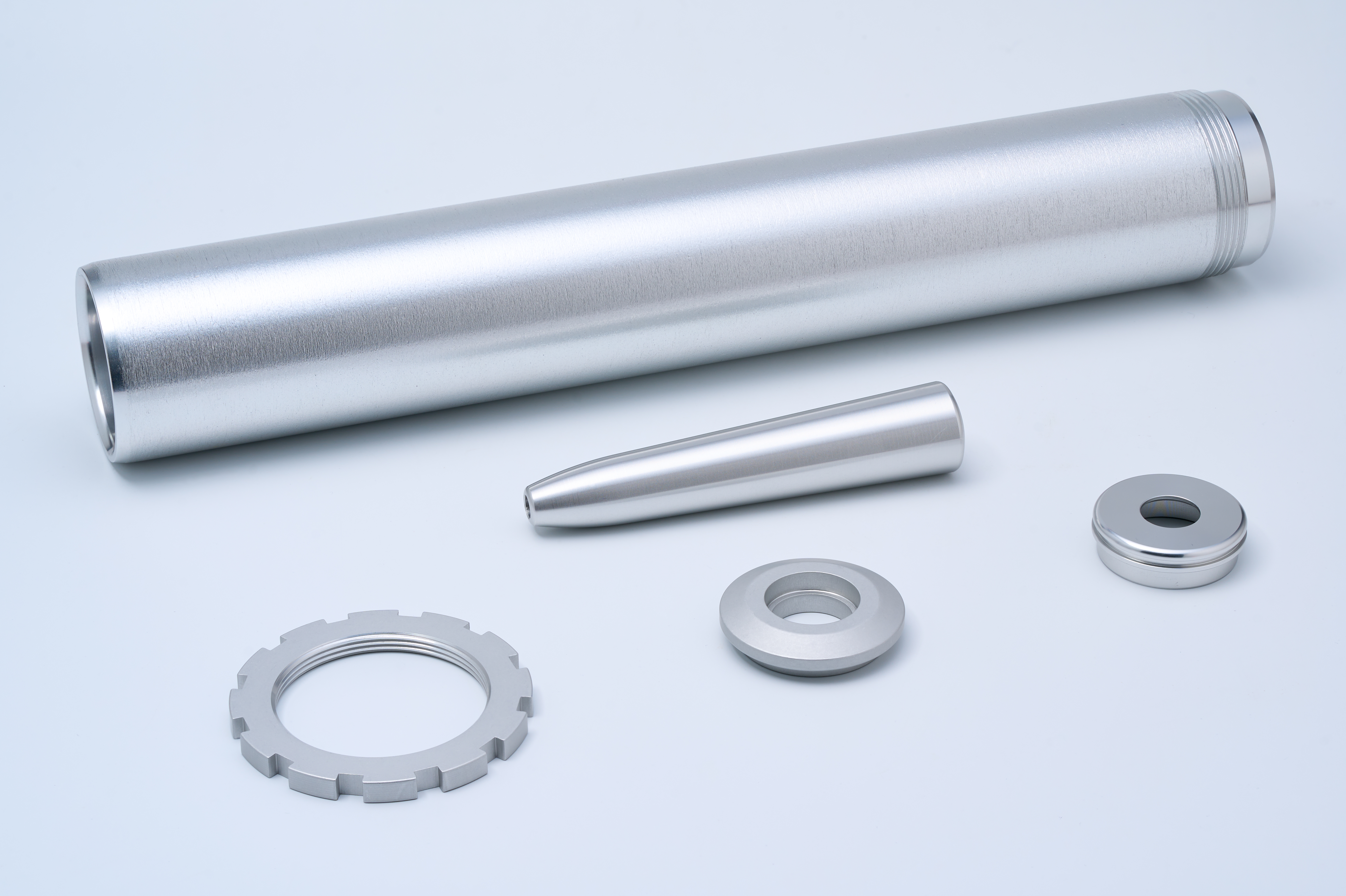

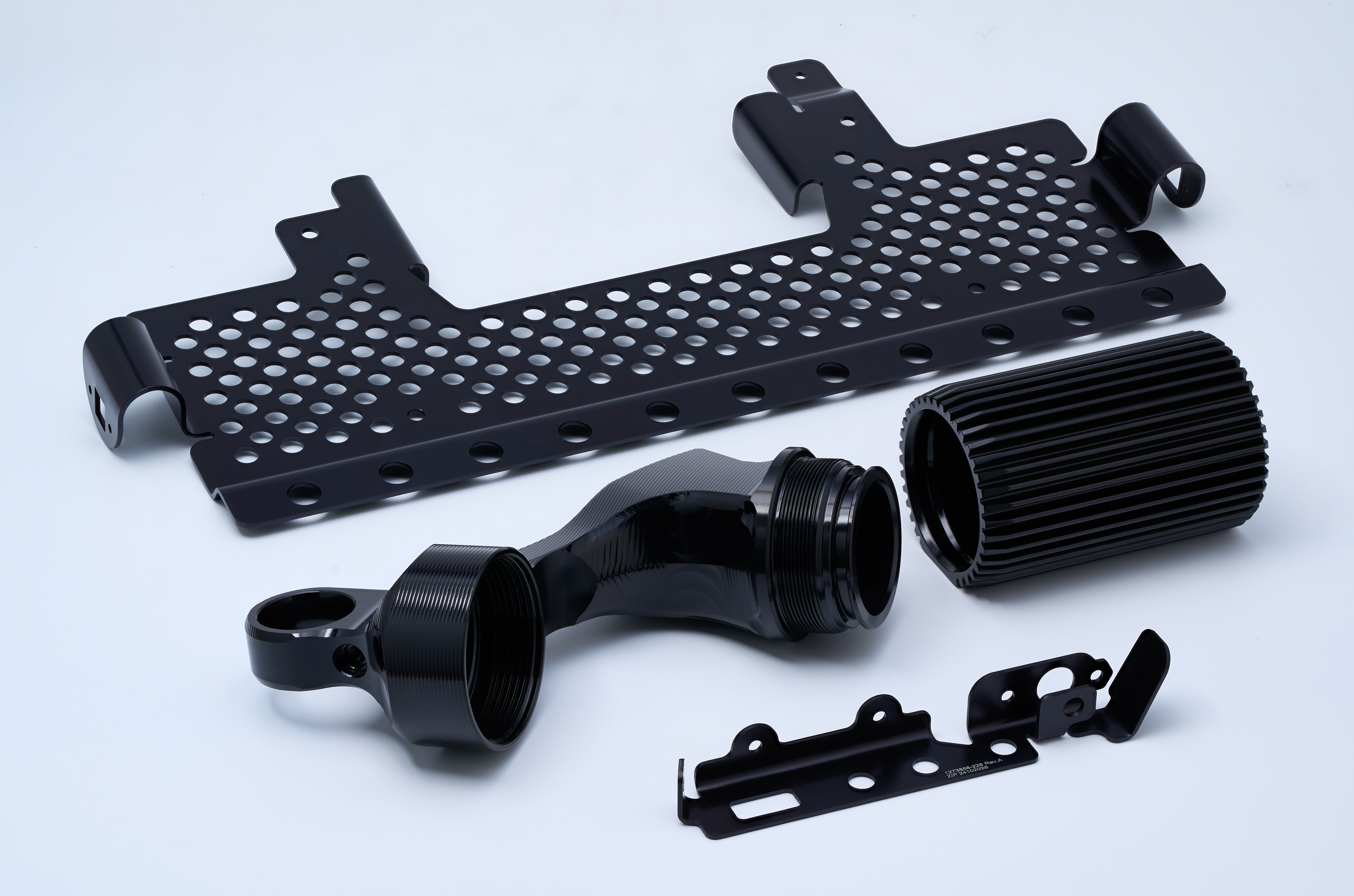

ZIP Metal Works specializes in aluminum anodizing to enhance durability, provide corrosion resistance, and improve the aesthetic quality of components.

Key Services and Capabilities:

- Services Offered: The company can perform both Type II and Type III anodizing, supporting parts for the aerospace and automotive industries.

- Anodizing Types: Capable of doing both soft and hard anodizing.

- Colors: Services include many colors, such as Red, Black, Gold, etc..

- Industries Served: Ready to serve the automotive, aerospace, and electronics industries, as well as general customers , both in Thailand and internationally.

- Jig Design: The company can design custom jigs (Jig) in-house to support the anodizing process and optimize compatibility with customer products.

- Specification Compliance: Capable of meeting customer requirements and technical specifications.

Key Selling Points:

- Experienced Staff: The organization has personnel with extensive experience in aluminum anodizing.

- Certified Processes: Anodizing processes comply with ISO 9001 and Nadcap standards.

- Customer Trust: Has been audited by customers from the automotive, electronics, and aerospace industries, who continuously recognize and trust the services.

- Advanced Automated Systems: Utilizes modern automated systems with barcode-based production orders, ensuring consistent quality.

- Environmental & Safety Compliance: Adheres to RoHS and environmental standards , with inspections conducted by reputable institutions such as SGS.

- Production Capacity: Possesses the capability, speed, and sufficient production capacity to meet customer demand.

Request a Quote for Anodizing Services

Request a Quote for Anodizing Services in Thailand

Looking for reliable anodizing services with consistent quality and fast turnaround? Partner with ZIP Metal Works for trusted aluminum finishing solutions tailored to your needs.

- Call us: 061-695-4145

- Email: info@zip1993.co.th

Zip Metal Works Factory 1993

Zip Metal Works Factory 1993 122/4 Moo 1 Bangnamchued Meung Samutsakorn Samutsakorn 74000

Contact us

saleniti@zip1993.co.th

Our Service

News & Articles

Contact Us

Terms of Service

Privacy Policy